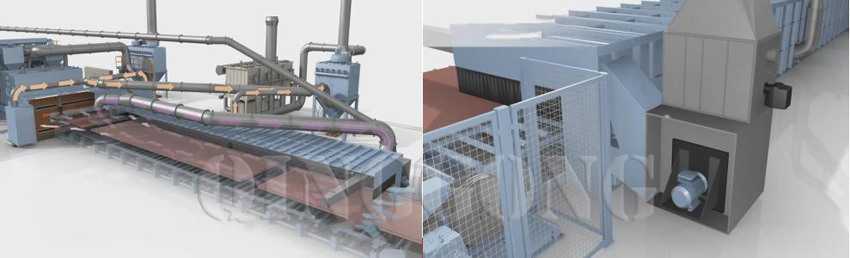

1. Workpiece conveyor system

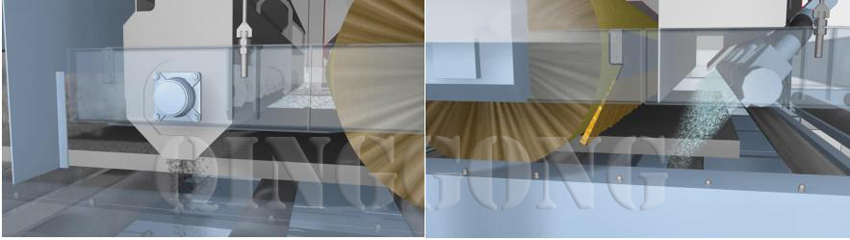

The whole roller conveyor system adopts frequency control step-less speed regulation, is able to synchronous running, each department is capable of independent action.

Blast cabinet’ rollers are with special wear-resistant sleeves to prevent blasting abrasion.

Plate chain conveyor with "v" shaped structure, painted steel short-term exposure to avoid film damage.

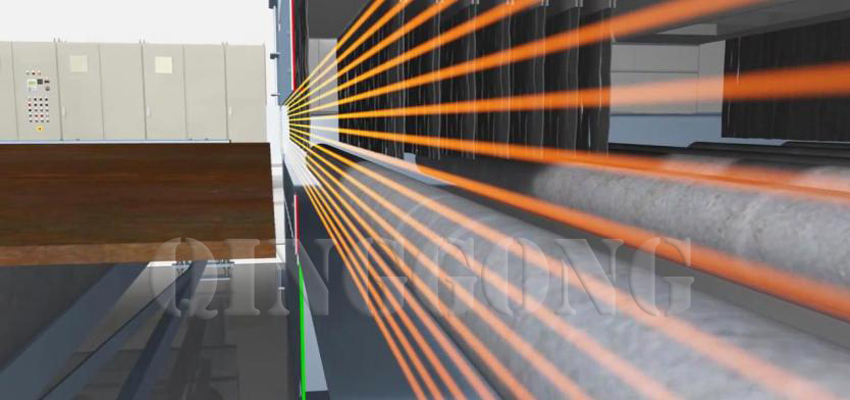

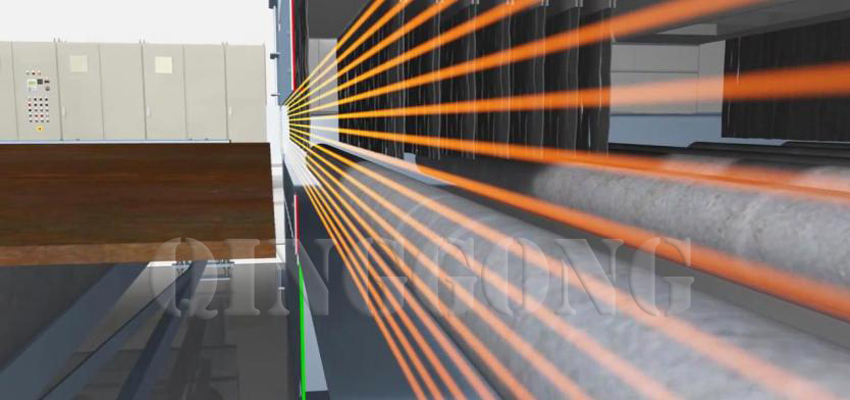

2. Blasting cleaning

Workpiece detection (measure height) adopted world-famous brand photoelectric detection, workpiece width measurement device send a signal to PLC so as to

automatically adjust abrasive feeding valve opening number.

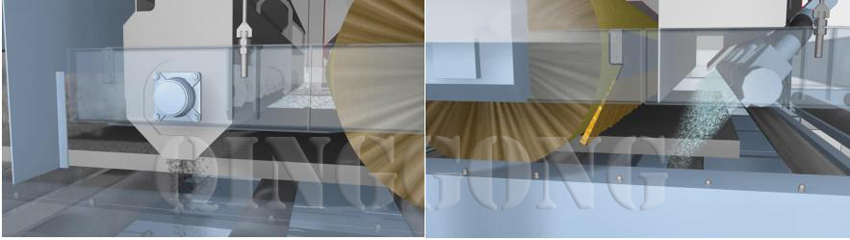

3. Abrasive cleaning up

First level: Brush+abrasive reclamation

Second level: high-pressure blower blow the workpiece twice one after another after blast cleaning

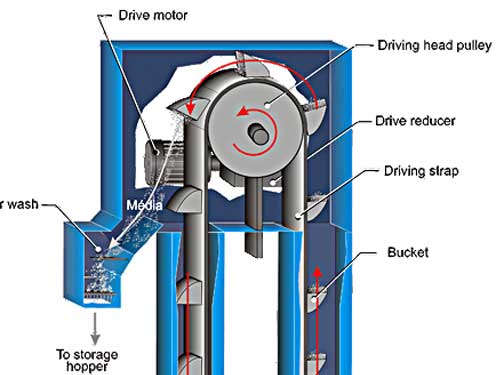

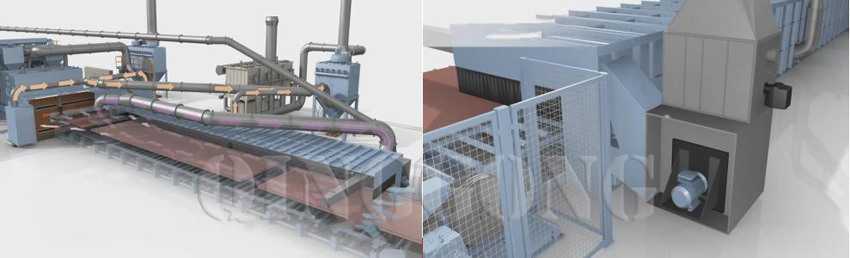

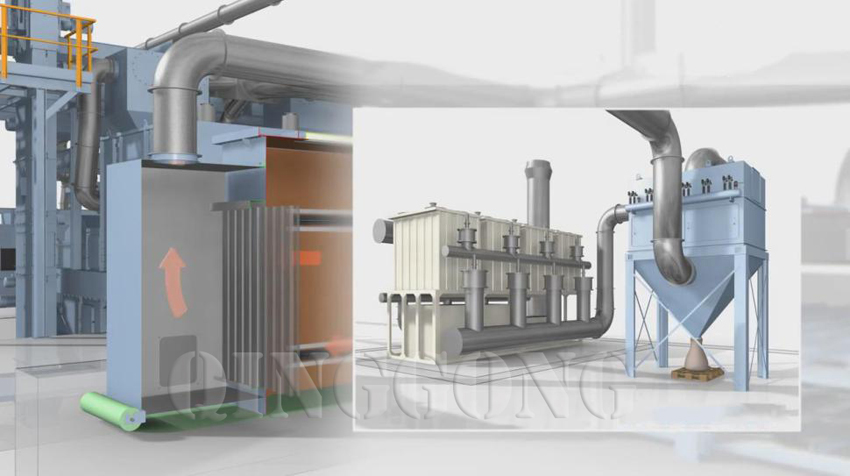

4. Abrasive reclamation system

Each of the abrasive reclamation system drive points equipped failure alarm function.

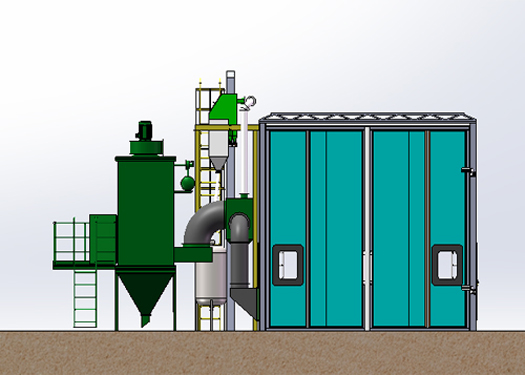

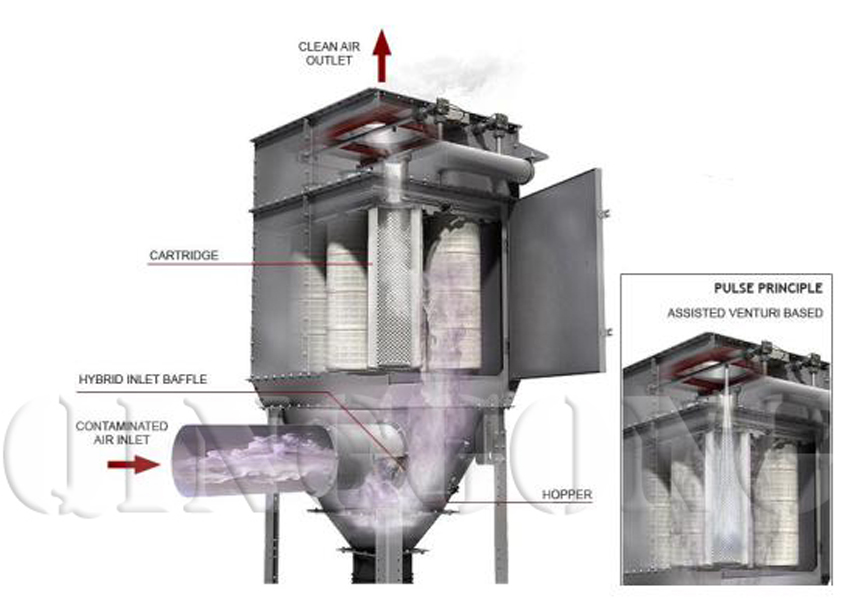

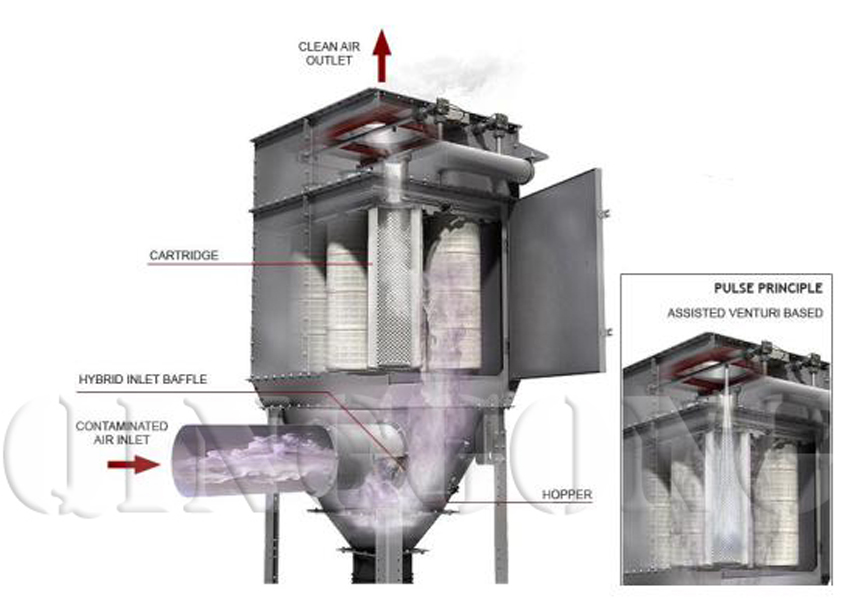

5. Dust collector system

Using HR4-48 Donaldson filter material cartridge dust collector, the dust removal efficiency ≥ 99.5%, dust emission is less than 30mg/M3.

6. Spray room

Adopting GRACO X45DL4 high-pressure Airless spraying pump, compression ratio 45:1, flow 38L/min,

Using a standard linear guide trolley, frequency conversion buffer on both ends of trolley stroke. Workpiece detection and transmission system separated from the spray gun set, paint mist interference-free, easy to clean paint scale.

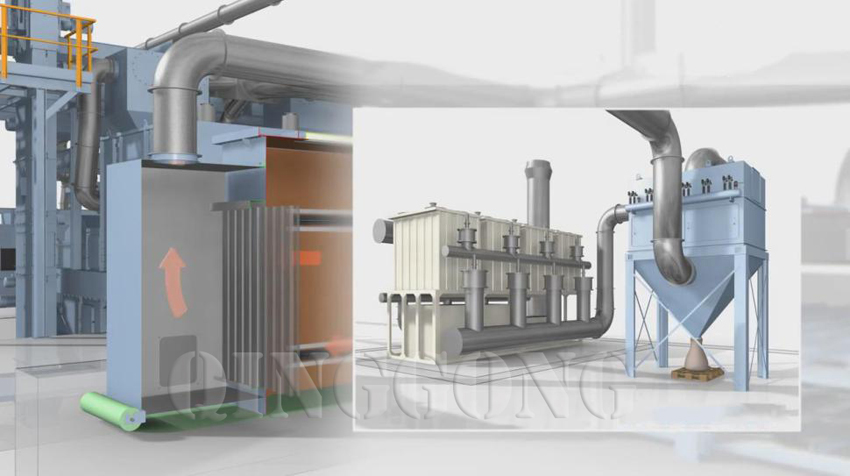

7. Drying room

Adopt dielectric Heaters and hot air circulation principle so that the heat can be fully utilized.

Drying room temperature adjustable from 40℃ to 70℃

Plate chain conveyor systems increase the eccentrical wheels, which saved the problems of deviation and high rate failure.

8. Paint mist filtration devices and harmful gas purifier

This system has automatic explosion-proof alarm function for paint mist concentration. Adopt advanced cardboard to filter paint mist, it is maintenance-free within one year, using activated carbon for adsorption of harmful gases. After this system it will be in accordance with the air pollution emission standards. (Paint mist emission standard ≤ 120mg/M3, p-xylene: emissions concentrations ≤ 70mg/M3, the 15 meters height exhaust pipe allows the secondary emission rate is 1.0kg/h. )

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  ไทย

ไทย  Polska

Polska  română

română